Client Background: Customer uses aluminum in their manufacturing process

Application: Remove ions from water using ion exchange process

Our Solution: Provide Deionization system to further purify city water

Client Background: Customer uses aluminum in their manufacturing process

Application: Remove ions from water using ion exchange process

Our Solution: Provide Deionization system to further purify city water

Client Background: Customer uses copper in their manufacturing process.

Application: Precipitate and remove copper from the waste stream.

Our Solution: Provide an Inclined Plate Clarifier (IPC) with integral dual chemical injection chambers. A mixer is mounted in each of the chambers.

Client Background: Packaging plant that specializes in aluminum cans.

Application: Remove oils and metals from waste stream.

Our Solution: Provide a complete wastewater system including on site project management and programming assistance. System includes the following:

Client Background: Forging, machining and heat-treating solutions.

Application: Remove heightened levels of oil from waste stream.

Our Solution: Provide a 150 GPM Oil Water Separator to remove free and dispersed oils from customers waste stream.

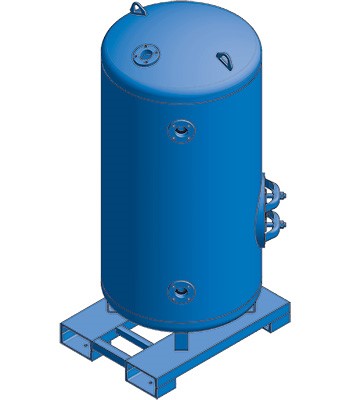

Client Background: Manufacturer of aluminum cans.

Application: Removal of unwanted impurities from the water via deionization technology.

Our Solution: Provide several carbon steel DI tanks. Customer supplied all parts and assembled themselves.

Client Background: Truck assembly in Detroit, MI

Application: Sludge dewatering

Our Solution: A 178 cubic foot, 1500mm x 2000mm filter press to dewater sludge. The press includes the following options:

Client Background: Manufacturer of etched and formed micro sheet metal parts.

Application: Metals removal

Our Solution: A complete skid mounted Inclined Plate Clarifier system to remove metals from the water. System includes the following:

All equipment is mounted to an A36 carbon steel skid for quick installation and start-up.

Client Background: Car manufacturer in Detroit, MI.

Application: Sludge dewatering

Our Solution: A 100 cubic foot, 1200mm filter press to dewater sludge. Press includes the following options:

Client Background: Car manufacturer in Mexico

Application: Sludge dewatering

Our Solution: A 55 cubic foot, 1000mm filter press with semi-automatic plate shifter, automatic pump control system and drip trays. Completely assembled and ready for installation on a concrete pad.

Client Background: Customer provides water treatment solutions for companies in the oil and gas, pipeline and construction industries.

Application: Remove oils and solids from a waste stream.

Our Solution: A complete turnkey mobile DAF system, including feed pumps, a Chemical Addition System, transfer pumps, Inline Mixing System, Dissolved Air Flotation clarifier, effluent holding tank, and effluent transfer pumps. System also includes Class I, Div. II motors and control panel.